As a reloader, you know that quality brass is worth its weight in gold. Especially with current prices and sometimes limited availability of reloading brass, it's important to make your brass last as long as possible. One of the most effective methods to dramatically extend the life of your cases is annealing - the process of heat-treating the case neck. In this article, we explain why annealing is so important, how it actually works, and what equipment you need to do it yourself.

What is annealing and why is it so important?

Every time you fire a cartridge, the brass of the case is subjected to enormous pressure and heat. The neck area of the case in particular undergoes significant deformation as it expands to release the bullet. When reloading, you then push the case neck back into shape. This repeated process of expansion and contraction causes metal fatigue.

After several reloading cycles, the brass becomes harder and less flexible - it "work hardens" as the technical term goes. This ultimately results in:

- Neck splits and possible cracks in the case neck

- Inconsistent grip on the bullet, affecting your precision

- Shorter lifespan of your expensive brass

- Reduced safety during shooting

- Problems during the sizing process when reloading

Annealing solves this problem by heating the brass of the case neck in a controlled manner to a specific temperature (approximately 340-400°C). At this temperature, the crystal structure of the brass softens again, restoring its original flexibility. The result? Cases that last up to three times longer and deliver more consistent shooting performance.

Common mistakes when annealing - and how to avoid them

Annealing may seem simple - "just heat it up and done" - but there are several pitfalls that beginning reloaders can fall into:

Mistake #1: Overheating the cases

Heating for too long or too hot can lead to brass that's too soft, which can be dangerous because the case may rupture during firing. This is not only bad for your firearm but also potentially hazardous for the shooter. The right balance in temperature and time is crucial for successful annealing.

Heating for too long or too hot can lead to brass that's too soft, which can be dangerous because the case may rupture during firing. This is not only bad for your firearm but also potentially hazardous for the shooter. The right balance in temperature and time is crucial for successful annealing.

How do you avoid this? Use temperature indicators like Tempilaq or temperature sticks that change color at specific temperatures. These help you determine the exact moment when you've reached the correct temperature. Modern annealers like the AMP Mark II DB fully automate this process and eliminate the risk of overheating.

Mistake #2: Heating the wrong parts of the case

A common beginner mistake is heating the base of the case. It's important to only heat the case neck and not the lower portion with the primer pocket. The base must remain hard to withstand the intense pressure during firing.

How do you avoid this? Use an annealer with consistent positioning, such as the Ugly Annealer, which ensures that only the case neck is heated. You can also use water cooling by submerging the case base in water during annealing, which prevents heat from spreading to the base.

Mistake #3: Inconsistent annealing between cases

If you anneal manually, it's almost impossible to give each case exactly the same amount of heat for exactly the same duration. This inconsistency can lead to variable flexibility in your case necks, which in turn results in variable grip on the bullets - and ultimately reduced shooting precision.

How do you avoid this? Invest in an automatic annealer that guarantees a consistent heat source and duration for each case. The Mark II DB Induction Annealer or the Vulcano Induction Annealer are excellent options for this.

Comparing different annealing methods

There are several ways to anneal cases, each with their own advantages and disadvantages. Let's compare the three most commonly used methods:

Flame-based annealing

This is the traditional method where a flame is used to heat the case neck. It's the most accessible method for beginners due to relatively low startup costs.

Advantages of flame-based annealing:

- Lower purchase costs compared to induction annealers

- Easy to understand process

- Works with virtually all calibers

- Minimal technical knowledge required

- Systems like the Ugly Annealer automate a large part of the process

Disadvantages of flame-based annealing:

- Less precision in temperature control

- Requires continuous purchase of gas

- Potential fire hazard

- More difficult to be consistent between cases

- Visual assessment of correct temperature is subjective

The Ugly Annealer is an excellent example of a modern, flame-based annealer. With its hopper system, automatic rotation, and precise positioning, it solves many of the disadvantages of traditional manual annealing. You will still need a soldering torch and gas cylinder.

Induction annealing

Induction annealing uses electromagnetic induction to make the molecules in the brass move, resulting in heat generation. This is the most modern and accurate annealing method.

Induction annealing uses electromagnetic induction to make the molecules in the brass move, resulting in heat generation. This is the most modern and accurate annealing method.

Advantages of induction annealing:

- Exceptionally accurate temperature control

- Perfect reproducibility between cases

- No open flame or fuel required

- Much faster than flame-based annealing

- Pre-programmed settings for different calibers

Disadvantages of induction annealing:

- Significantly higher purchase costs

- Requires electricity

- Some models need special adapters for different calibers

- Technically more complex

The Mark II DB Induction Annealer from Annealing Made Perfect (AMP) is generally considered the gold standard in induction annealing. With its pre-programmed settings for virtually every caliber and the AZTEC mode for self-analysis of your brass, it offers a level of precision and reproducibility unattainable with traditional methods.

For those who want an induction annealer but don't have the full budget for an AMP, the Vulcano Induction Annealer is an excellent alternative that still offers the benefits of induction annealing at a lower price point.

Water-cooled annealing

This method combines flame-based annealing with water cooling to prevent heat from spreading to the base of the case.

Advantages of water-cooled annealing:

- Protects the case head from heating

- Can be done with simple equipment

- Less chance of overheating the base

- Relatively inexpensive to set up

Disadvantages of water-cooled annealing:

- Requires more manual handling

- Can be messy due to water use

- Difficult to maintain a consistent process

- Water droplets can cause unwanted cooling

How often should you anneal your cases?

A frequently asked question among reloaders is how often you should anneal your cases. There is no universal answer to this question, as it depends on several factors:

- Caliber and pressure: High-pressure calibers like .300 Win Mag cause more metal fatigue than lower-pressure calibers like .223 Remington

- Quality of the brass: Premium brands like Lapua and Norma often have higher quality brass that lasts longer

- Degree of resizing: Full-length resizing causes more stress than neck-sizing

- Intended use: For competition shooters who need maximum precision, more frequent annealing is recommended

As a general guideline, you can follow:

- For precision competitions: Anneal after every 1-3 reloading cycles

- For recreational shooting: Anneal after approximately 5-7 reloading cycles

- For hunting ammunition: Anneal after 3-5 reloading cycles

A good indication that it's time to anneal is when you notice that the case neck feels stiffer during the sizing process, or when you have difficulty getting consistent grip tension on your bullets.

Which annealer suits you?

Let's look at the three main annealers in our range and who they're most suitable for:

Mark II DB Induction Annealer - The professional choice

The Mark II DB from Annealing Made Perfect is the Rolls-Royce of annealers. With a price tag of €1,949.50, it's a serious investment, but also one that's more than worth its money for the serious reloader.

Key strengths:

- Pre-programmed settings for virtually every caliber

- AZTEC mode for analyzing your own brass

- Laboratory-level precision and reproducibility

- No work coil that burns out or needs replacement

- Completely safe and enclosed system

Who is this the best choice for? The Mark II DB is ideal for professional or semi-professional shooters, competition shooters who want to get the most out of their ammunition, and reloading clubs that can share the costs. For those who process large quantities of cases, the time savings and consistency make the investment worthwhile.

Note: to use the AMP, you need the correct pilot for your specific caliber. These are available separately for €39.50 each.

Vulcano Induction Annealer - The best middle ground

At a price of €979.00, the Vulcano Induction Annealer offers an excellent balance between price and performance. It's a true induction annealer that allows you to anneal accurately and consistently without the premium price of the AMP.

Key strengths:

- Induction technology for precise heating

- Adjustable parameters for temperature and duration

- Suitable for all calibers from small to .50 BMG

- Relatively compact dimensions

- Good price-quality ratio

Who is this the best choice for? The Vulcano is perfect for the serious reloader who wants the benefits of induction annealing but doesn't have the full budget for an AMP system. It's also ideal for shooters who reload different calibers and value consistency.

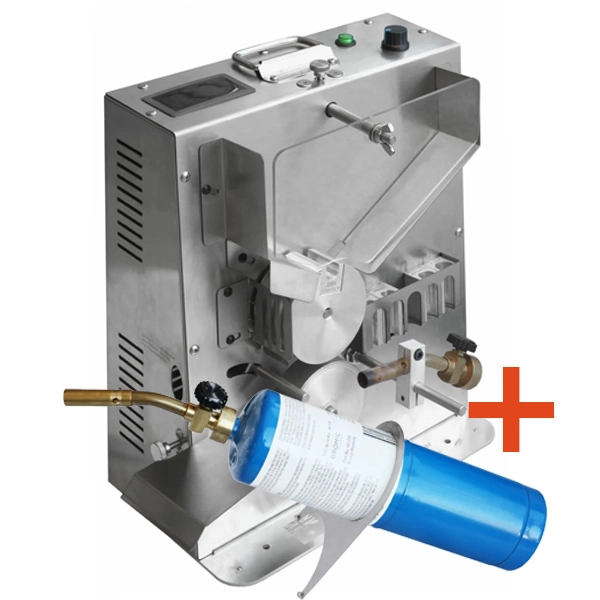

Ugly Annealer - The best entry-level option

At €299.00, the Ugly Annealer from Derraco Engineering is by far the most affordable option in our range. Despite the name and lower price, this is a surprisingly capable device that performs many times better than manual annealing.

Key strengths:

- Affordable entry-level model

- Hopper system for efficient loading

- Includes 5 CNC-machined caliber conversion inserts

- Virtually no wearing parts

- Robust construction of stainless steel and impact-resistant polycarbonate

Who is this the best choice for? The Ugly Annealer is ideal for beginners in annealing, occasional reloaders, or shooters with a limited budget who still want to benefit from the advantages of annealing. It's also a good option for those who want to experiment with annealing before investing in a more expensive system.

Keep in mind that for the Ugly Annealer you still need a soldering torch (€32.50) and gas cylinder (€22.50). We also offer a complete bundle with all necessary components.

Step-by-step guide for your first annealing session

Are you convinced of the benefits of annealing and have you purchased an annealer? Then it's time to get started! Here's a simple step-by-step guide to make your first annealing session a success:

Preparation

- Clean your cases thoroughly - Remove all dirt, grease, and powder residue. Dirt can lead to irregular heating.

- Sort your cases by caliber and brand - Different brands may respond differently to annealing.

- Ensure a safe working environment - Especially with flame-based annealing, good ventilation and absence of flammable materials is important.

- Read the manual of your annealer carefully - Each device has its own specific procedures.

The annealing process

For the Ugly Annealer:

- Mount the correct caliber insert in the machine.

- Mount the soldering torch in the adjustable clamp and connect the gas cylinder.

- Adjust the flame to a blue, focused flame.

- Fill the hopper with cleaned cases.

- Turn the wheel to bring the cases one by one into position at the flame.

- For most calibers, 3-5 seconds of exposure to the flame is sufficient - watch for a slight discoloration of the brass to a golden tint.

- Allow the cases to cool completely before handling them.

For the Vulcano or AMP Induction Annealer:

- Select the correct setting for your caliber (or use Tempilaq sticks with the Vulcano to determine the correct temperature).

- Place the correct pilot holder for your caliber (with the AMP).

- Follow the specific procedure for placing the case in the machine.

- Activate the induction via the control panel.

- The machine will automatically stop when the correct temperature is reached.

- Allow the cases to cool completely before handling them.

After annealing

After annealing, it's important to:

- Let the cases cool completely - Don't force the cooling process by using water or other coolants, unless specifically recommended in your annealer's manual.

- Visually inspect the cases - Look for signs of overheating such as extreme discoloration or deformation.

- Mark the annealed cases - Keep track of which cases you have annealed and when. A simple marking system with a waterproof marker or a separate storage system works well.

- Test before processing large quantities - First anneal a small batch of cases and test them thoroughly before processing large quantities.

- Run the annealed cases through your normal reloading process - They are now ready to be used again.

The result: what can you expect after annealing?

After correctly annealing your cases, you will notice several improvements in your reloading process and shooting results:

- Longer lifespan of your cases - On average, annealed cases last 2-3 times longer than non-annealed cases, resulting in significant cost savings in the long run.

- More consistent neck tension - This results in a more uniform grip on the bullet, contributing to better ballistic consistency.

- Reduced standard deviation in muzzle velocity - This leads to more accurate shooting results, especially at longer distances.

- Fewer neck splits - One of the most common problems in reloading is drastically reduced.

- Smoother sizing process - Annealed cases resize more easily, resulting in less wear on your reloading dies.

Many shooters also report smaller groups at the shooting range after implementing annealing in their reloading process. This is especially noticeable when shooting at longer distances, where small variations in muzzle velocity translate into larger deviations on target.

Is annealing worth it?

We often get this question from beginning reloaders. The answer is a resounding yes, especially if you:

- Reload regularly and value consistency

- Want to get multiple reloading cycles out of your cases

- Shoot at long distances where precision is crucial

- Use expensive high-quality brass that you want to preserve as long as possible

- Want to optimize your shooting results without purchasing new equipment

Even with the simplest annealing setup, you will notice a clear difference in the lifespan of your cases and the consistency of your reloading results. And given the current prices of quality brass, even the most expensive annealer pays for itself if you reload regularly.

Frequently asked questions about annealing

Since we regularly receive questions about annealing, here's some additional information about this process:

Should I anneal before or after resizing my cases?

This is a subject of ongoing debate among reloaders. Most experts recommend annealing after resizing, but before filling with powder and seating the bullet. The logic behind this is that resizing causes the metal fatigue you want to restore by annealing. If you anneal before resizing, you do restore flexibility, but you immediately cause metal fatigue again during the resizing process.

Can I anneal any type of case?

In principle, you can anneal all brass cases. However, nickel-plated cases require specific attention because the nickel layer reacts differently to heat than pure brass. RWS cases with the well-known greenish color can also be annealed but may require adjusted settings. Steel cases are not suitable for annealing.

How do I know if I've annealed my cases correctly?

The correct annealing temperature is reached when the brass gets a subtle golden discoloration. When using temperature-indicating substances like Tempilaq, the color will change at the correct temperature (usually around 340°C). With induction annealers like the AMP, you simply follow the pre-set programs.

A practical test is to compare an annealed and a non-annealed case side by side during the sizing process - the annealed case should feel noticeably smoother.

Can I over-anneal my cases?

Yes, over-annealing is a real risk, especially with flame-based methods. If you overheat the case neck, the brass becomes too soft, which can lead to stretched necks or even ruptures during firing. This is why consistency and temperature control are so important in the annealing process. Modern induction annealers like the AMP Mark II virtually eliminate this risk.

In summary: A small investment for big improvements

Annealing is without doubt one of the most effective measures you can take to extend the lifespan of your cases and improve the consistency of your reloading process. Whether you choose a simple solution like the Ugly Annealer or invest in a high-quality induction annealer like the AMP Mark II - the improvements in performance and cost savings in the long term make the investment more than worthwhile.

For serious shooters and reloaders, annealing is not a luxury but an essential practice that contributes to better shooting results, less waste of expensive brass, and a more efficient reloading process. Start annealing today and experience the difference for yourself!

Do you have questions about annealing or would you like personal advice on which annealer best suits your needs? Feel free to contact us. Our team of experienced shooters and reloaders is ready to help you make the right choice.

Also check out our other reloading supplies such as measuring tools, reloading presses, and reloading dies to complete your reloading setup.